The scale-up process from laboratory to industrial scale entails adapting and optimizing processes for larger-scale production. This evolution involves a technology transfer (TT), which is not limited to lab-scale origins. It can also encompass industrial transfers between manufacturing sites or from a partner to a CDMO services provider. In all cases, it involves the systematic transfer of data, processes, methodologies, and technical know-how to ensure consistent and reliable performance at the new scale or location.

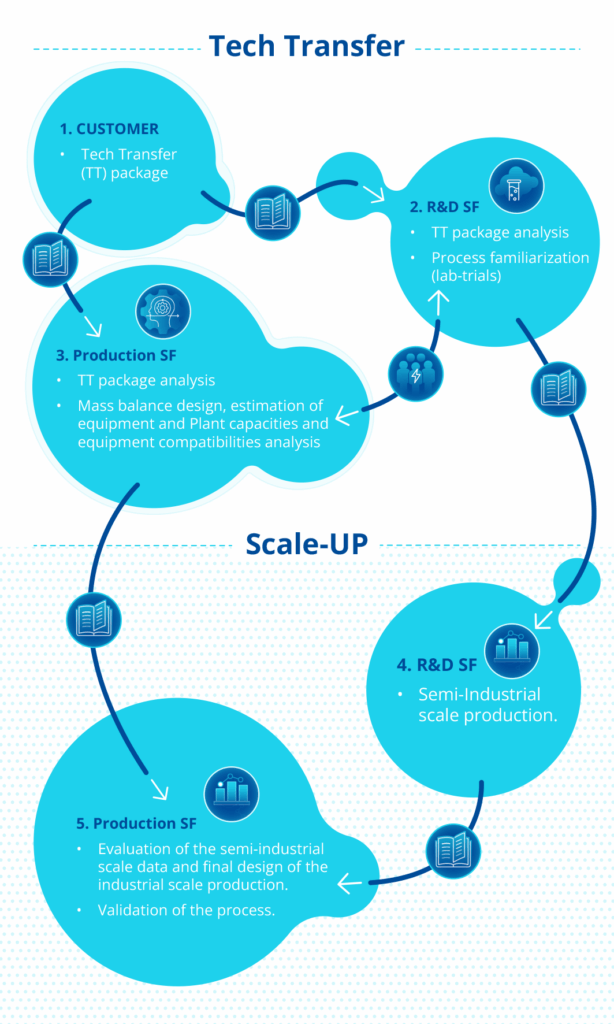

In the case of a CDMO Organization like Suanfarma, the scale-up and the prior technology transfer can be divided in a few stages and summarized in the following figure:

Each one of the presented stages comprises a series of crucial challenges for the success of the Scale-up. Regarding the production area, these challenges arise in stages 3 to 5 and are as follows:

- Stage 3 – At this stage a preliminary analysis of the TT package is carried out to estimate the production capacities and evaluate the potential equipment to use. The main challenges of tis stage are:

- Have all the necessary information in the TT package.

- Have adequate knowledge of the Plant and available equipment as well as their functionalities. – It is critical to ensure that the equipment and process make a “perfect fit” in all aspects, such as chemical compatibility, right technologies, etc.

- Perform a preliminary risk assessment from the HSE point of view.

- Stage 4 – At this stage the R&D team and the production must work together for a successful first scale-up. The main challenges here are:

- Ensure the participation of operational staff from the production sector and not only technical staff.

- Approximate (if possible) the conditions of this scale to the conditions existing in the industrial plant to use in the next stage.

- Collect and understand all the critical data/parameters necessary to the next stage planification.

- Permanent communication and collaboration between the R&D team and the production personnel.

- Have good data from the prior stage.

- Develop methodologies to ensure a proper cleaning of the equipment.

- Stage 5 – The final Scale-up to the industrial are done at this stage. The main challenges of tis stage are:

- Adapt the stage 4 process to a facility with different equipment and technologies.

- Ensure that the adaptations of the plant and equipment to the new product will not have a negative impact on other previously existing products.

- Always monitor and advise the departments and/or companies that carry out changes to the installation and equipment.

- Ensure that all employees have access to information and solid training.

- Maintain the communication between the R&D team and production to overcome some possible obstacles during the first batches execution.

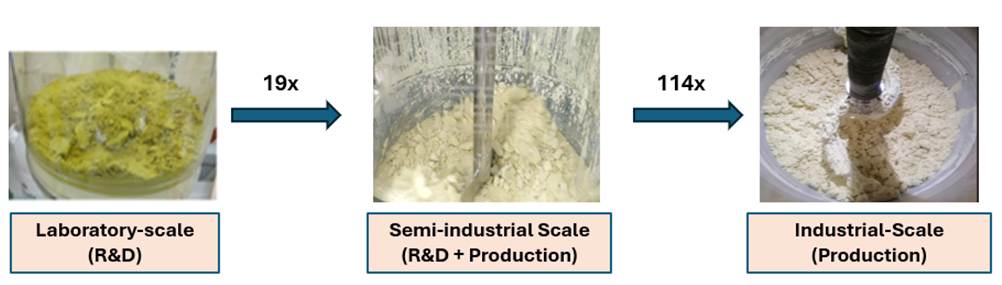

Practical example: All these phases were covered in validation process, in which the following scale-ups were carried out:

Most of the referred challenges were observed during the TT. The teamwork of R&D and production was crucial in the success of this Tech Transfer. Several studies were performed by R&D, such as, compatibilities studies or solubility tests of the product, which allowed the production team to select the right equipment for the process, as well to develop efficient cleaning procedures

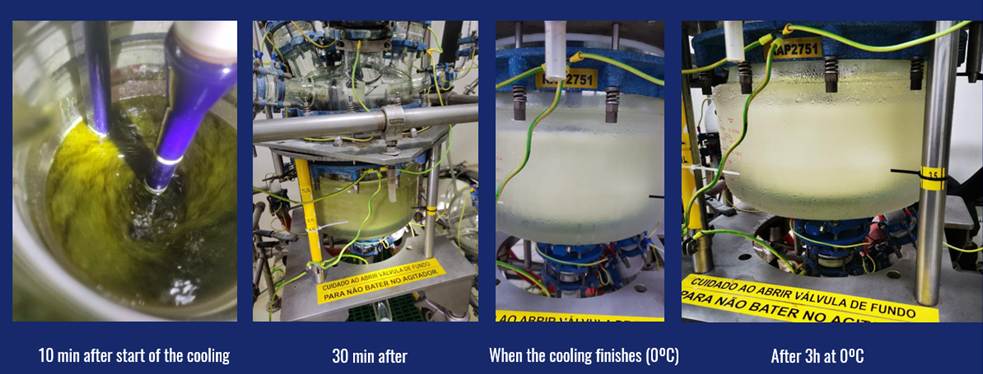

In the semi-industrial scale-up stage (stage 4 of the 1st figure), Production participation was essential as the technical staff and the operators were able to immediately meet the characteristics of the process and some details like the evolution of precipitations steps:

This type of knowledge was crucial to the stage 5 success since it allowed production to understand at this and other stages whether the process behaviour and the appearance of the product were normal.